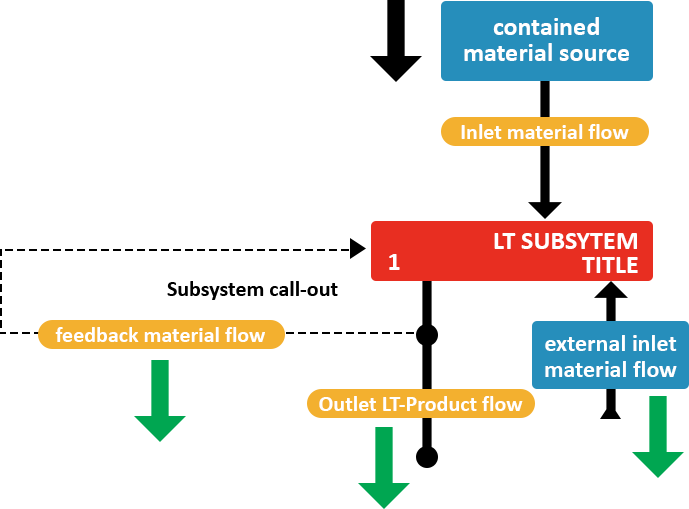

LT Waste Power Water Schematic

If we do not deliver what we promise, will dismantle plant and handover vacant land!

|

||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

Toxic

Nothing released

in air or ground

Residue

If anything, is ionized

Redundancy

100%

Combustible

Nothing stored or

used

Explosive

No processes or

materials usedused

Monitoring

24 x 7 through LT

Satellite